-

Call: +91 99625 26458

-

Email: info@danishbs.com

Operation

The Principle of Operation

The principle of operation of Danish Business Services Private Limited (DBS) is to facilitate a winning situation for companies in high-cost countries through optimized solutions for their business requirements – either Cost-competitive “Services” OR “Products” from India through thorough understanding of the requirements, mutual efforts, open-book cost-calculations and with a full level of transparency!

-

No matter Strength or Strategy, no Business can achieve maximum benefits unless it is operating Efficiently

- The trick to winning in the market is buy Low, sell High.

Model Of Operation

What We Do

Build

- Manage formation of Indian Company as per customer need as Private Limited company or 100% Subsidiary of Parent Company

- Identification of Facility / land and facilitate completion of contracts. Develop facility for Office / Manufacturing / Assembly line, Warehouse, Engineering center etc.

- Manage projects for setting up Operations, Installation, Testing and Commissioning

- Handling Recruitment or required Manpower. This includes Training and Induction as well and for both White collars and Blue collars.

- Ensure compliance to Indian statutory regulations

Operate

Design and Implement Manufacturing Process

Establishment of Logistics and Accounting procedure to handle both Imports and Exports

Arrange Warehousing and Despatch processes

Support implementation of ERP Systems to manage Business Processes like Buying operation – MRP, Purchase Order, Receivables and Payables, Quality and NC handling

Establish Banking and Finance Operations and Liaison with Government Departments for Tax and Statutory Compliance

Transfer

- Legal and Operational formalities & procedures established. (Import / Export / Local)

- Trained & Experienced manpower

- Optimized Processes set - fulfilling local Govt needs & legal requirements and suiting Customers’ requirements.

- Fully Established Teams – Procurement & Logistics, Warehousing, Technical Support, Finance, HR & Admin and Production.

- a Fully functional Manufacturing OR an Engineering set-up

‘An Office away from Office’ is the concept through which this model is built up for customers who would like to have their own resources placed in Chennai at significantly lower cost levels who would work for them exclusively, virtually – however without any legal and operational hassles. This exclusive set-up in Chennai will function as an ‘Extended Arm’ of the company in a high-cost location with Cost-plus pricing. As per customers’ requirements competent resources will be hired at competitive cost levels, trained and provided to the customers to be able to work for them exclusively ‘as their full-time employees’.

The “Extended Arm” Model

HUB

- Is the centralized exclusive office in Chennai established for a particular customer in a high-cost location. Size of Hub will be based on the number of FTEs, nature & volume of tasks being offshored from other locations of this company.

- Depending upon the need & nature of tasks, some tasks can be carried out in Chennai Hub in full and some to the level of 80%

- Chennai Hub will function based on agreed processes & procedures and on ‘an exclusive extended arm’ model.

- Office in Chennai., wherein all OR in some cases 80% of the tasks are carried out with exclusive FTEs.

SPOKE

- Offices of this customer in high-cost regions wherein the balance 20% of the tasks (what not done in Chennai Hub) is being carried out for specific reasons.

- Offices of the same customer in other locations wherein the remaining portion (say 20%) of the tasks is carried out.

Advantages of the ‘Extended Arm’ model

- Customer owns the resources exclusively & fully and pays for the FTE cost in India – however without any legal, operational & other hassles

- Customer-resource ownership is more. Customer feels that their own resources are placed in Chennai and the employees feel the same belonging too.

- Knowledge sharing is easier

- More utilization is possible through direct communication & coordination.

- Chennai team functions as an ‘extended arm’ of the Customer

- Performance management is easier as the resources are assigned to the customer on exclusive basis.

“Hourly-rates” Model and “Project-based” execution

- While we promote the advantages of FTE model of service significantly, we do undertake projects and execute tasks based on Hourly-rates also.

- This is for specific engineering requirements and IT projects.

- The pricing model is as explained in the table shown.

Model of Operation.. (the ‘Hourly-rates’ OR ‘Project-package’ model)

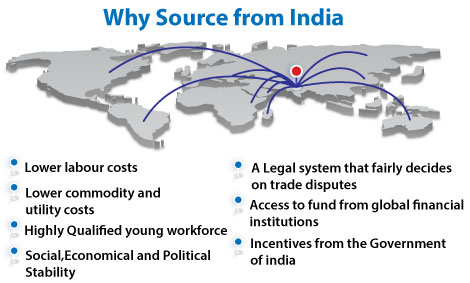

Best-cost country sourcing

If you are looking for establishing a supply-chain operation from India, you’ve reached the right place.

- Our team has experienced Techno-commercial engineers who are helping companies in the US and Europe to carry out bench-marking study through ‘bottom-up cost modelling techniques’ and to source different categories of products from the Indian supplier-base.

- As an experienced organization in this field, we fulfil the sourcing needs of our clients by providing end-to-end solutions including Should-cost modelling, Value engineering, Raw material analysis and optimization through nesting possibilities, Supplier assessment and approvals, Pricing negotiation and Contract finalization, Product development including sample development and PPAP approvals, P Ordering and Buying processes, Logistics arrangement, and thus taking care of the complete Supply chain management – in a most optimized way possible, to make sure our customers get high-quality products at competitive price levels on landed-cost basis!

- We have built a highly stable network of suppliers in India in all categories and have helped global companies gain a competitive edge in their market-share through sourcing from India.

- As a part of handling everything in a most transparent way, we connect our Customers with the Suppliers in India directly while we facilitate every step in establishing the supply chain operation for them.

Your involvement in the sourcing process will be to share requirements, review quotes, test and validate samples and receive timely delivery of goods through placing Purchase Orders directly to the concerned suppliers with fully transparent operating-conditions – while we stand responsible for the secured operation of the end-to-end supply chain including Logistics handling!